Photos

Specifications

Tunings

Home

Kevin Kastning on the C2

hen

Kevin first approached me with the desire to build a

14-string Contraguitar, I can say that one of my personal emotional

responses was trepidation. I had built 7-string baritones as a special

instrument to take to the NAMM show when I was with

Santa Cruz Guitars

(SCGC), and a number of other instruments that were solidly outside the norm

and they always seemed to take forever to sell. In short, I had become very

resistant to building instruments that fell outside the envelope.

hen

Kevin first approached me with the desire to build a

14-string Contraguitar, I can say that one of my personal emotional

responses was trepidation. I had built 7-string baritones as a special

instrument to take to the NAMM show when I was with

Santa Cruz Guitars

(SCGC), and a number of other instruments that were solidly outside the norm

and they always seemed to take forever to sell. In short, I had become very

resistant to building instruments that fell outside the envelope.

Kevin, on the other hand had been an SCGC artist endorser and friend for close

to 10 years at that point, and we had a perfect record when it came to building

unusual instruments. Each of which had been successful for Kevin in terms of his

ability to incorporate them into his music and in fact to allow him to evolve

his music in a direction that would have been impossible without those

instruments.

Both the KK Baritone (DKK), and the

KK Baritone 12-string (DKK-12) were outside of what

SCGC had previously done (longer scale lengths etc), and while others had built

baritone guitars with these longer scales before us, the intended range was

higher than those intended by Kevin. This meant that while the KK Baritone

wasn't entirely new in terms of scale length and the naming identification of

baritone, it was new in terms of requirements such as string gauge, required

tuners, etc. "A" tuning is standard (if there is such a thing as standard tuning

for baritone guitar).

Kevin now tunes the KK Baritone to essentially a

6-string bass tuning (EADGBE), but had originally tuned it to F# (a whole

step above a bass tuning). However, the intention of an acoustic bass guitar is

usually as a bass rhythm instrument. Kevin uses a lot of harmonics and wants

significant overtone support and isn't using it as essentially a rhythm

instrument, but instead primarily a melodic instrument. High-tension strings and

tunings suitable for creating a hard-driving bass line kill the resonance,

complexity of overtone support, and harmonics required for creating Kevin's

musical vision.

These differences mean that Kevin and I have had to modify tuners to take larger

strings, as well as extensive research and experimentation on string gauges,

tensions, etc.

The KK Baritone 12-string took things a bit further and enabled Kevin to start

tuning what would normally have been octave or unison strings to varying

intervals relative to the root strings allowing a stunning complexity in chord

voicings and tonal palette.

When Kevin wanted to start work on the 14-string Contraguitar, I was still at

SCGC and was concerned about the fact that it would be difficult to build it

profitably, and that it would not fit well within the context of a boutique

custom shop whose success required quantifiable production each and every day.

Guitars falling in and out of production cost the company a lot in terms of

productivity.

Furthermore, the tension on this instrument would greatly exceed anything I had

even thought of building before. I wanted to stay with an X-braced system like I

was accustomed to, and felt that the KK12-string, though having fewer strings

and tuned higher across the board, had shown that an X-brace should be able to

support the extra tension. At some point as we discussed the instrument and its

unique engineering, we inevitably had the discussion regarding how we wanted to

approach it, possibly overbuilding to ensure its longevity or go with my

intuition....and erring on the side of a light and responsive instrument capable

of delivering the balance and tonal requirements Kevin required, with the

possible (but unlikely, I felt) outcome that it could be prone to tension

problems. Kevin was clear that he did not want an instrument that would hold up

but not give him tonal satisfaction and that he was willing to trust me along

these lines. He never wavered in his belief that based on previous

collaborations, I would be able to design and voice this instrument if anyone

could. That kind of faith from such an amazing talent as Kevin goes a long way

towards creating confidence and fearlessness, but it also carries a terrible

liability. He had explained to me that his chosen musical vision depended on the

success of this instrument. His compositions were already demanding the tonal

palette and range this instrument would provide. On the other hand, I also knew

that such a stellar talent would not be defeated in the case that the tension

proved too great. Either we would find another way to build the instrument or he

would find another way to achieve his musical vision.

We went ahead with the design, and eventually tried to put it into the schedule,

but while there were always good intentions, it didn't really fit in a

production schedule and so eventually it was just decided that it wouldn't

happen at SCGC.

Kevin and I designed an Alto 12-string guitar (KK-Alto)

which fit more easily into the production, and about that time I left SCGC to

follow my own vision as a builder. Kevin came to me then and asked if I would

build the Contraguitar.

We thought we had most of the design solidified in our heads, so eventually,

after getting the new company going, I agreed.

It turned out as we moved forward we had to make many changes; for one thing

Kevin was able to play more extended range instruments and was able to mach up

some test necks and fingerboards etc., and discovered that with the string

spacings he required, neither a 16-string nor an 18-string would be possible.

The KK12-string was built more along the lines of a normal 12-string in terms of

neck width, and as his playing style evolved and with intervallic tunings

required additional technique evolution, he had found more and more that he

required string spacings between the courses based on classical guitars, which

also constitute a part of Kevin's guitar palette. This meant that the DKK-12 had

become almost unplayable in utilizing his most contemporary techniques and

stylings. To incorporate that kind of wide spacing, 14-strings turned out to be

just about the maximum possible strings, and with one single scale length, we

would later find that the range we had agreed upon limited the highest course

(A) to tight intervallic or unison tuning; octave tuning wasn't possible for the

high A course. Similarly, on the bass side, the next lower step (B) proved

physically impossible with only a 30” scale length. We had reached the limits of

range without variable or multiple scale lengths at exactly the point that Kevin

was limited in terms of width of neck!

Kevin received the first Contraguitar in September 2010, and by November 2010 he

was already using it in a recording session with

British guitarist Mark

Wingfield. During that first three-day recording session which resulted in

enough material for 2 CDs, Kevin used the Contraguitar on 2/3 of the recordings.

By the end of that recording session, Kevin said he had established that the

Contraguitar had established itself as his main instrument, and that he needed

another so that he could keep one in Concert tuning and the other in specialized

intervallic tunings, which can take considerable time to tune and in some cases

can even require special string gauging to optimize.

In November 2010, Kevin asked me to build another Contraguitar. Kevin and I

refer to the first Contraguitar as C1 and the second as C2. Over the next 12

months, Kevin had at least 10 important recording dates with

Alex De Grassi,

Carl Clements,

Michael Manring,

Gilbert Isbin (a Lutenist from Belgium), cellist

David Darling, and

another with Mark

Wingfield. As time went on, though C1 proved itself to be capable of hanging

in there for the long haul, we had a number of minor issues surface regarding

bracing, bridge, etc. The 300-400 lbs. of string tension was causing a drop in

the top in front of the bridge and a belly behind the bridge. While this is

fairly common even in standard 6-string instruments, especially in light

sensitively-built instruments, the additional tension caused me some concern. As

little issues started to surface, Kevin sent C1 back to me a couple of times.

Upon investigation I saw that the extra tension had caused a minor opening of

the X-brace junction, and was causing some minor issues with the bridge as well.

I removed the strings and reglued the X-brace, and then I capped it so that it

could never open again like that. Since then, I not only incorporated that

detail into C2, I also incorporate a beautifully detailed and carved brace cap

on all my other steel string guitars now. I also carved and glued in a small

radiused and scalloped brace running along the front edge of the bridge plate to

additionally support the top and sound hole in front of that heavily loaded

bridge. With minimal added mass but increased integrity, it actually improved

the sound, as well as structural integrity. The bridge tip and bellying was

stabilized at a very acceptable level, has great future integrity, and the tone

has just gotten better and better.

On C2, I altered the bracing to include three smaller tonebars, increasing the

integrity of the top behind the bridge without adding much mass at all, Added

the brace in front of the bridge plate as well as two short small braces shoring

up the front and rear legs of the X, one on the treble side and one on the bass.

These 3 extra braces are all small and short, similar to the side struts or

finger braces, and add very little mass compared to the overall increase in

tension, yet they allow C2 to be as light and responsive as C1 while the top

appears absolutely solid with no trace of bridge tip whatsoever!

Kevin asked that since we had chosen to use European maple as the back and side

wood for a completely different tonal palette, and given his preference for the

classical guitar and violin aesthetics, that we try to do a violin-like finish.

First we tried using a shellac finish as the tint but the amber colors we used

weren't dark enough and tended to just make the guitar yellowish amber and very

bright. I then decided to mix a tint that I would eventually call Cremona Brown,

from a combination of tobacco brown, mahogany red/brown, and amber. I used these

colors to tint the first couple of coats of lacquer and sprayed that over the

shellac, thereby preserving the amazing chatoyance that comes with shellac,

while deepening the color to a nice rich violin color. I didn't like the idea of

leaving the ivoroid binding dark, the same color as the wood, but Kevin

preferred it that way and in the end I felt that it made it look much more

related to the violin family aesthetic, and quite elegant. Good call, Kevin!

We also went with a compound radiused fretboard.

C2 is proving to be a wonderful musical companion to C1, and is structurally

quite an interesting engineering solution considering the tension supported by

this still thin and fairly lightly braced top.

Next stop for Kevin and I will be two 16-string classical guitars for Kevin and

his musical collaborator and well-known Hungarian guitarist,

Sándor Szabó.

Speaking for myself I can't imagine a more challenging and fulfilling

relationship than the one that has unfolded between maestro Kastning and myself.

The degree of challenge I encounter in these projects is somewhat intimidating,

often frightening, and always gratifying!

- Daniel Roberts,

Daniel

Roberts Stringworks

Belgrade, MT

January 2012

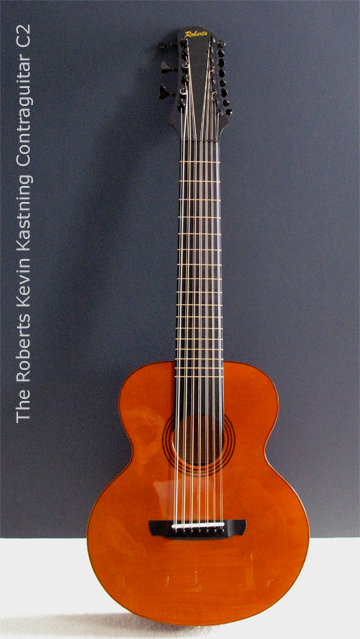

14 strings

European flame maple back and sides

Body depth: 5.25 inches at tailblock (13.3 cm)

Carpathian red spruce top

3.25 inch nut (82.5 mm)

30-inch scale (762 mm)

Ebony headplate overlay

All maple/dyed maple purfling and rosette

Bracing/voicing: double-tapered, knifed, and scalloped

Three tonebars + asymmetrical finger braces

Flamed red maple neck and heelcap

Banjo-cut headstock profile

Ebony fingerboard (12" to 18" compound radius)

Jescar EVO frets

17 frets with a fretless area in the upper register above 17

7-pin ebony

bridge

Bone compensated 1/4-inch saddle

Maple bridge plate

Ebony nut

Ebony unslotted bridge pins

Cremona violin stain

Tuners:

Gotoh compact bass (3)

Steinberger (3)

Grover locking mini-Rotomatics (8)

E (bass) thru A (alto)*

For C2 string gauges, see the gauge chart.

*This is the octave tuning; I will be using many intervallic

tunings, such as the DKK-12 examples on

the tunings page. There are more

tunings possible, and I will post those soon.

This photo gallery chronicles the birth of C2, from tonewood selection in November 2010 to completion in December 2011. Hover over the center of the photo for navigation controls.